Major Research Facilities

RF/DC Reactive Magnetron Sputtering with TMP and MFCs

To coat the metal oxide-based composite thin films for Electronic/Energy devices

Thermal Evaporation Coater

To coat the metal electrodes for device applications

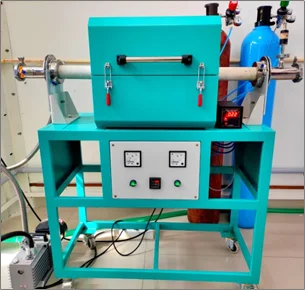

Tube Furnace-CVD (Alumina tube, Temperature up to: 1200°C)

To coat the 2D-materials for electronic/energy device applications

Fume hood for wet-synthesis

To synthesize the nanostructured materials using chemical methods

Muffle furnace (Temp: 1050°C ± 2°C), Oven (Temp: 150°C ± 2°C) & Spin Coater

To anneal the as-grow samples to improve the crystallinity/structural properties (using furnace/Oven) and coat the thin films (using spin coater)

Gas Sensor measurement system

To measure the target/toxic gases to develop gas sensor device

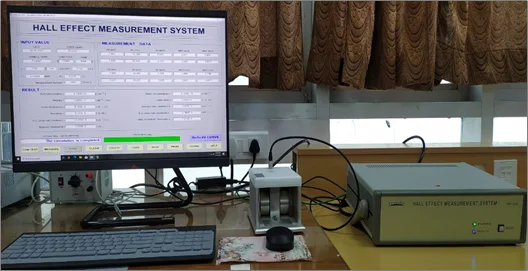

Hall measurement system (Ecopia HMS-3000)

To measure the resistivity, carrier concentration, mobility of semiconductors

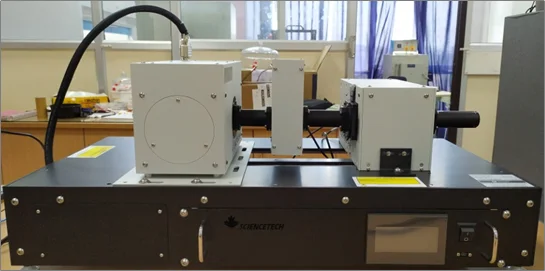

Tunable Light Source (300-1800 nm)

To use as a light source for photodetector and gas sensor device characteristics

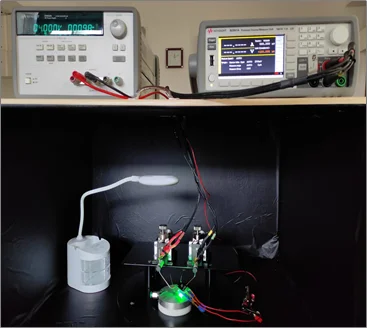

Custom-made probe station with Keysight Source Measurement unit (SMU-B2901A & Programmable Power supply (E3632A)

To measure the I-V, photodetector, and bolometer device measurements

3-D Printer (Creality CR-6 SE model)

To print the device measurement parts and flexible substrates